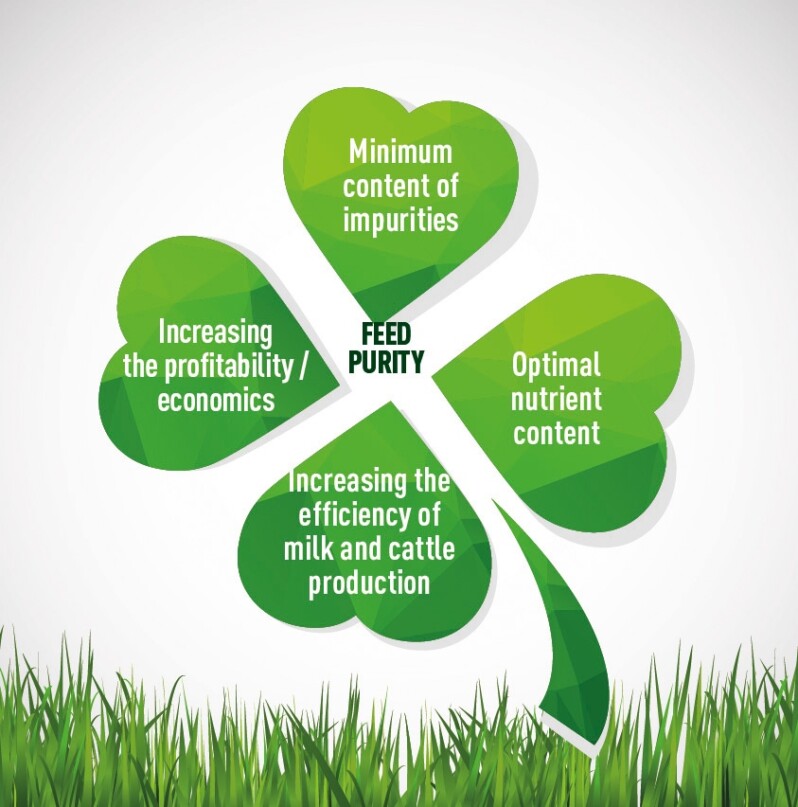

Farms dealing with milk production and cattle breeding require feed of the highest quality. For this reason, we recommend using SaMASZ machines for harvesting green fodder, which guarantee optimum harvesting while preserving the highest possible content of nutrients. This translates into the efficiency of milk production and the health condition of the herd, thus helps maintaining a competitive advantage. It is extremely important to take care of the quantity and quality of the feed, as the number of processes associated with its preparation always results in losing the nutritive value (such losses can be as high as 50%). SaMASZ machines minimize the mechanical and natural factors affecting the harvesting of green fodder. They reduce the content of impurities, optimize the quantity of nutrients, increase the efficiency of milk and cattle production, which translates into a higher profitability of the farm.

All technologies incorporated in SaMASZ machines serve to reduce the loss of the nutritive value, and ensure its purity and more economical harvesting of green fodder.

MINIMUM CONTENT OF IMPURITIES IN THE FEED

When harvesting green fodder, it is required to minimise the impact of negative environmental factors, such as:

• inorganic contamination of the feed (soil, stones, etc.),

• washing out the nutrients by rainfall,

• organic pollutants - microbial activity, decay, mould growth, browning of green fodder, development of thermophilic bacteria.

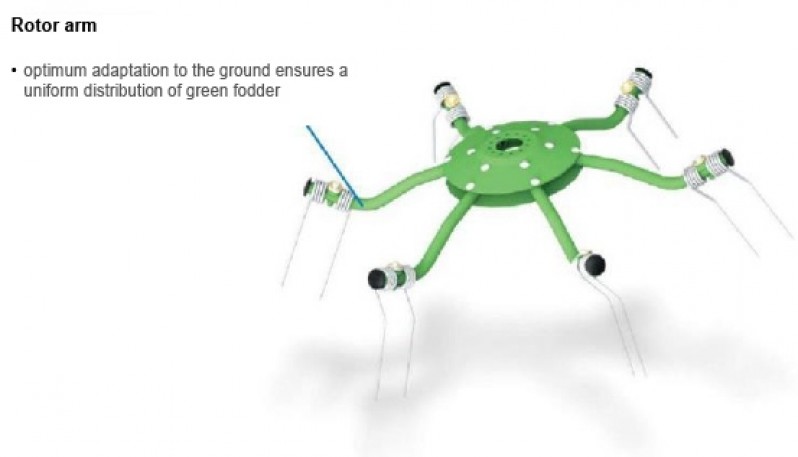

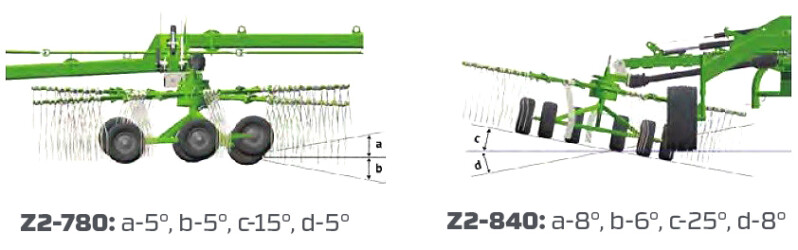

This is why it is so important to use machines, which eliminate the negative factors throughout the entire process of harvesting green fodder - from mowing, through tedding, raking, and harvesting. The quality of the feed is also influenced by the way it is stored (it should not be frozen, damp, dried, or exposed to contamination).

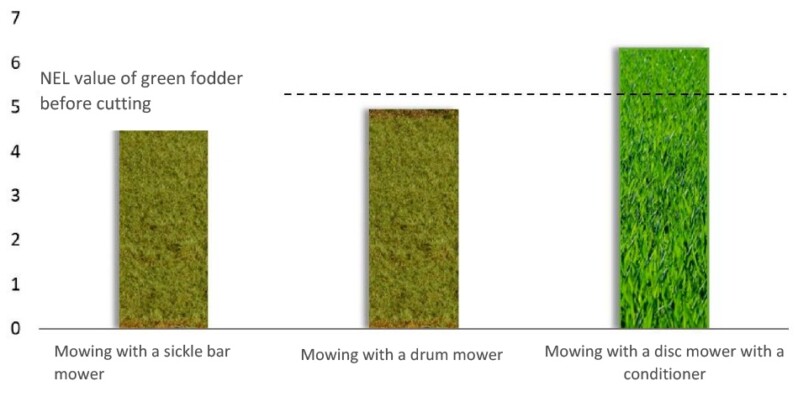

THE OPTIMUM NUTRIENT CONTENT IN THE FEED

The basis for the proper feeding of dairy cattle is to fully satisfy the need for nutrients, depending on the physiological condition of the animal. The level of nutrition provided for dairy cattle varies during the various lactation periods, mainly depending on the volume of milk production and body weight.

Bulky feed and nutritive fodders are used as the feed for dairy cattle. Taking into account the physiological requirements of the ruminants and the significant economic aspect, most of the feeds in the ration are comprised of bulky feeds (they can make up to 80% of the total ration), which means that their high quality is extremely important. The right feed, in terms of the optimum quantity of nutrients, is obtained by the proper selection of machines and the correct setting of their parameters, as well as the correct timing of the agricultural processes (mowing, tedding, raking, and harvesting).

INCREASING THE EFFICIENCY OF MILK AND CATTLE PRODUCTION

The factors influencing the efficiency of milk production have both genetic (breed, individual) and environmental (e.g. nutrition, cattle living conditions, climatic conditions) bases, which are considered to be of higher importance. The correct feeding method helps achieve very rapid changes in the milk yield. It stabilises and optimises the fat and protein content of milk, while maintaining the good health and fertility of cows.

High quality feed prevents the occurrence of common metabolic diseases (e.g. acidosis), udder inflammation, and eliminates reproductive problems. Such diseases have a direct impact on the milk yield.

INCREASING THE PROFITABILITY / ECONOMICS OF THE FARM

High quality feed translates into the profitability of the farm, because:

• it helps achieve lower feeding costs (the better the quality of the bulky feed, the more the cow can consume, and therefore use less of the nutritive fodder to achieve the assumed weight gain)

• helps maintain and improve the health of the herd

• The ‘tastiness' affects the amount of feed consumed by cattle, and its nutritional quality affects the amount of energy and assimilation of nutrients

• contributes to the high milk yield and quality

• helps meet the physiological requirements of

cattle breeding

Feed of the highest quality is the only guarantee of producing large quantities of milk, while maintaining high health status of the herd, which translates into a positive economic result.